How Does It Work

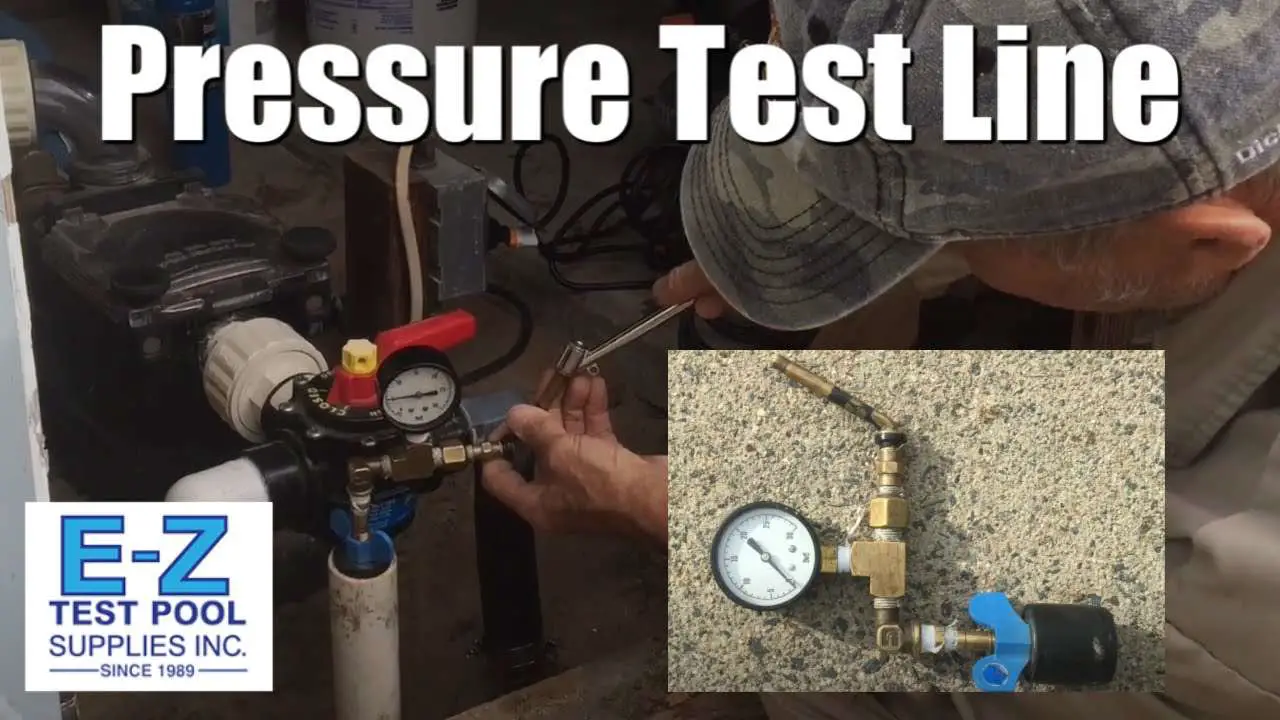

Connect a garden hose to the green valve, while the pressure tester stick is firmly threaded into a skimmer. From the starting skimmer, you can isolate certain lines, one at a time, pressurizing the line for 5-10 minutes, while you watch the pressure gauge. No pressure drop, no leak!

You can use these types of pool pressure testing devices to verify the integrity of new or old plumbing, or if you are trying to find the source of a leak in your own pool.

If Your Pool Is Losing Water You May Need To Test To See If The Leak Is Coming From The Pvc Plumbing Here Are 5 Steps That Will Show You How To Make Your Own Pressure Text Device And Determine If There Is In Fact A Leak

1. Construct a pressure testing tool as shown in the diagram below and connect it to the pool PVC lines.

2. Test either the entire system at once or each PVC line separately. Install a pressure test plug in each return, skimmer and main drain.

3. Use the attached pressure test tool to put water in the PVC lines.The lines should be mostly full of water and not just air. Remove one of the plugs if necessary to fill the pipes with water then reinstall the plug. Continue to add water until the pressure reaches about 20-25 psi.

4. Turn off the valve on the pressure test tool and watch the pressure gauge. If the pressure goes down rapidly, there is a leak in the PVC pipe. Be sure and check the pressure test plugs to make sure they are not leaking. If the pressure goes down slowly there is a small leak. If there is no leak the pressure should hold for several hours.

5. If the pressure goes down you will need to test each line individually to locate the leak. If the PVC pipe is under a concrete deck, you can add an air valve to the pressure test tool. Use an air tank or compressor to add air to the water pressurized line. Look for the water bubbling in cracks or use a stethoscope to listen through the deck for the leak.

Didn’t find the answer you were looking for? You can always contact us at [email protected] or choose the category below to see our most frequently asked questions for that topic:

How Much Does It Cost To Find A Pool Leak

The cost for pool leak detection varies, depending on what method youre using or if you decide to hire someone.

A DIY kit can cost anywhere from a few dollars to $30 or $40. Hiring a professional can cost quite a bit more. FIXr lists the national average for this cost at $900 but shows it can run up into the thousands for things like cracked beams or complete tile replacement.

You May Like: Liquid Chlorine Shock Calculator

Found A Leaking Pipe Now What

After pressure testing the pool lines, and finding one that does not hold pressure, what are the next steps? Either you make a repair to the broken pipe, replace the broken pipe, or abandon the broken pipe.

1. Repair the broken pipe: for this to happen, you have to know at least the general area where the pipe is leaking, so you know where to dig. Many skimmer and return breaks can be under the pool deck, and Ive tunneled under many short decks, and also cut a 3×3 hole in large pool decks to fix leaks. But dont start digging or cutting until you are at least reasonably sure of the location. Leak detection experts often also add a gas to their pressure testing rigs, and then use electronic listening devices to hear exactly where the leak is in the pipe. With a small bit of experience, they can draw an X right on the ground dig here.

2. Replace the broken pipe: If you dont know exactly where the pipe is leaking, or if the entire pipe is shattered along its length, or if you are replacing old flex pipe used underground, you may just want to dig a new trench , from the pump to the pool, and lay in a new pipe. Dont worry about digging up the old pipe, just let it rot in the ground.

How To Do A Pressure Test On A Return Line

Hi,I have a 20K g vinyl pool woth 4 returns, 2 in the corner of tha pool, and 2 in the steps. The 2 in the steps were disconnected at the pump by the previous owner and the return outlets plugged with these winterizing plugs.I think they might be leaking if not I would want to put them back in service. What do I need to do a pressure test on them ? I have a compressor but what kind of fittings do I need and where can I get them ? I have not been able to find stuff through google.Thanks

- 1,423

Don’t Miss: How To Store Pool Towels Outside

Pvc Plumbing Pressure Testing

If your pool is loosing water and you have checked and eliminated all four possible causes in our previous article, the leak could be in the PVC plumbing.

1. Construct a pressure testing tool as shown in the diagram and connect it to the pool PVC lines.

2. Test either the entire system at once or each PVC line separately. Install a pressure test plug in each return, skimmer and main drain.

3. Use the attached pressure test tool to put water in the PVC lines. The lines should be mostly full of water and not just air. Remove one of the plugs if necessary to fill the pipes with water then reinstall the plug. Continue to add water until the pressure reaches 20-25 psi.

4. Turn off the valve on the pressure test tool and watch the pressure gauge. If the pressure goes down quickly, there is a leak in the PVC pipe. Be sure and check the pressure test plugs to make sure they are not leaking. If the pressure goes down slowly there is a small leak. If there is no leak the pressure should hold for several hours.

5. If the pressure goes down you will need to test each line individually to locate the leak. If the PVC pipe is under a concrete deck, you can add an air valve to the pressure test tool. Use an air tank or compressor to add air to the water pressurized line. Look for the water bubbling in cracks or use a stethoscope to listen through the deck for the leak.

We hope that helps! If you are still experiencing issues, let us know the comments.

Pool Pressure Test Stick

- Male x female hose valve

- 1/8-inch threaded air valve

All of these items can be found at Home Depot or at a plumbing supply company.

Just glue the materials together with PVC glue and you are ready to test your underground plumbing lines for leaks or pressure loss.

Some folks looking for a leak in a pool will use a different type of pressure-testing device, one that will also allow them to use air from a small compressor.

Using air makes it easier to hear a pool leak, if you are using listening devices, to pinpoint the exact location of a leak along the line.

This pool pipe pressure tester uses only water, but you could insert an air valve into the air bleeder hole so you can also pressurize with air, if desired.

Recommended Reading: When Does Jones Beach Pool Open

How Does Pool Leak Detection Work

Finding a pool leak yourself is sometimes pretty hard to do, especially if its a tiny little liner tear or puncture.

But we listed 2 methods to try. These both include different steps to find the most common types of leaks.

The bucket test works by allowing you to see if your pool is losing water due to evaporation or an actual leak. And the ink test shows you where water is seeping out by watching the flow of the dye.

Professional leak detectors use items like electrical probes to track the sources of least resistant connections. These send them audible frequencies letting them know where the voltage is weak.

They also might use a pressure method where they can tell where the plumbing is losing water pressure.

Is Your Pool Leaking

Before running out to buy these materials to pressure test your whole pool to find a pool leak, first check the basic sources of pool leaks: where the skimmer meets the edge of the pool, or the underwater light, or small cracks in plaster or tears in vinyl. Check that your backwash line is not leaking. Check the pump and filter carefully. Check for cracks in the tile line.

To determine how much of your water loss could be simply evaporation, do the bucket test.

Place a bucket of water on the top step or swim out of the pool. Mark the water level on both the inside and the outside of the bucket, as shown in the image. Shut off the pool pump for 24 hours and if the pool has lost more water than the bucket, then you have a leak in your pool. Repeat the exercise with the pump on for 24 hours. This can give an indication of whether the leak is suction side or pressure side. Next step would be to plug the lines, skimmers, returns, and cleaner line for 24 hours . Use threaded or rubber expansion plugs and see how much the pool leaks with all the plumbing plugged securely.

Read Also: Fishers Ymca Swim Lessons

Pressure Testing Tip: How To Check For Leaks In The Main Drain Without Plugging The Line

While plugging the main drain is the most accurate way to pressure test the main drain line, if you want to avoid getting in the pool, it is possible to identify a problem in the upper part of this plumbing by using a technique called an Air Lock Test. This test takes advantage of the fact that the water above the main drain in the deep end of the pool produces a measurable amount of pressure that acts as a plug to an air filled main drain line.

After pressure testing the rest of the plumbing lines to ensure they are sound, induce air into the equipment end of the main drain line until you see it bubble out of the main drain. Then, close the valve on your pressure tester. Assuming the main drain is under about 9 of water, the water column above it should provide 4 psi of pressure on the trapped air within the line. A pressure drop below 4 psi is an indication of a leak somewhere in the upper section of the plumbing. If the depth of the main drain youre testing is different than 9, the pressure the water puts on the air lock can be calculated at .43 psi per foot of water.

If there is a leak in the section of the line at or above the water level of the pool, youll see a quick drop to 0 psi.

How To Perform A Pool Pipe Pressure Test

When testing a pool for leaks, one of the first diagnostic tests is a pressure test. The plumbing lines are isolated and tested independently during this process to determine its ability to hold pressure without leaking. A pool pipe pressure test is only as accurate as the person performing the test, so it is essential to let a professional carry it out for you.If you fitted a plumbing system in a high-rise building, all plumbing lines would be pressure tested which including the following steps:

- The entire plumbing system to be installed should be combined into a single line for testing purposes.

- The system is charged between 150% to 300% of the value of the maximum designed operational pressure

- The system is loaded in increments , with a waiting period for each pressure level.

- Once charged to the maximum test value, the system is monitored for leaks for 10 minutes.

- If no leaks are discovered, the pressure is reduced to 150% of the systems maximum pressure and left for 24 hours.

- Any loss in pressure, even 1/4 lb in 24 hours, will fail the pressure test.

When you take these principles and apply them to the swimming pool industry, you need to know a few values. The first is the maximum working pressure of the pool system. 30 PSI is the standard maximum pressure that pool equipment must support. 50 PSI represents a severe maximum above which failure is expected. You must also know the maximum rated pressure of the plumbing materials used.

Read Also: Swimming Pools Easy Setup

Re: How To Do A Pressure Test On A Return Line

I would do a water pressure test instead of an air test. Plug one end of the pipe. For the other end use PVC adapters down to a 3/4 ” hose adapter. Use your garden hose to pressurize and fill the pipes. You might want to plumb in a pressure gauge as well. All the parts can be found at your local Home Depot PVC section and drip irrigation section.

How To Build A Pool Plumbing Pressure Testing Stick

When new in-ground pools are built, there comes a day when the plumbing crew rolls in and lays neat rows of PVC pipes into a trench. These pipes connect your pool with the pump and filter, pool cleaner, and maybe a waterfall or spa.

The final step before the trench is backfilled is to pressure test the plumbing to make sure that all the glue joints are good, and no cracked pipes exist. The plumber is careful to pressure test thoroughly and present a report to the general contractor so that he doesnt get blamed for damage to the pipes after he leaves.

This blog post is about how to build a homemade pressure tester stick that you can use to pressure test new or old plumbing. Think that your skimmer has a leak? Maybe the main drain? You can test all lines to and from the pool with our simple design. Note that we dont sell this pool plumbing pressure tester, but you can make one yourself with a few simple parts.

Don’t Miss: Iron Out In Pool Water

How To Pressure Test Pool Lines

Pressure Testing Pool Plumbing

Many of you have emailed me, asking about the follow-up piece and here it is 5 years later sorry for the wait! Essentially, you screw the pressure stick into the skimmer, with Teflon tape. Then connect a garden hose to it, also with Teflon tape on the male threads. Your pressure testing stick should be made with a 1.5 inch threaded male fitting on the end. If your skimmer has two inch ports, add a 2in. X 1.5in. threaded reducer to the skimmer, again with Teflon tape to prevent any pressure loss.

Then plug the pool returns, other skimmers, and the main drain, whatever pool pipes you want to test. You can use winter expansion plugs or use threaded plugs with o-rings, like the SP1022C or 195829 for 2 inch threaded pipes. You dont have to plug them all at the same time, because you will be testing each line individually. There are specialty test plugs that have straight side walls, not tapered like winter plugs, which hold better under high pressure. However, in most cases, these expensive test plugs are not needed, and winter plugs will hold 10-20 psi of pressure, as long as you tighten the wing nut very tightly. If you have problems, use the threaded plugs mentioned above.

If you are just testing the suction side , dead-head a valve at the pump . If you dont have a 3-way valve in front of the pump, you can open the pump lid and put a plug firmly into the incoming pipe.